Innovative Underwater Solutions

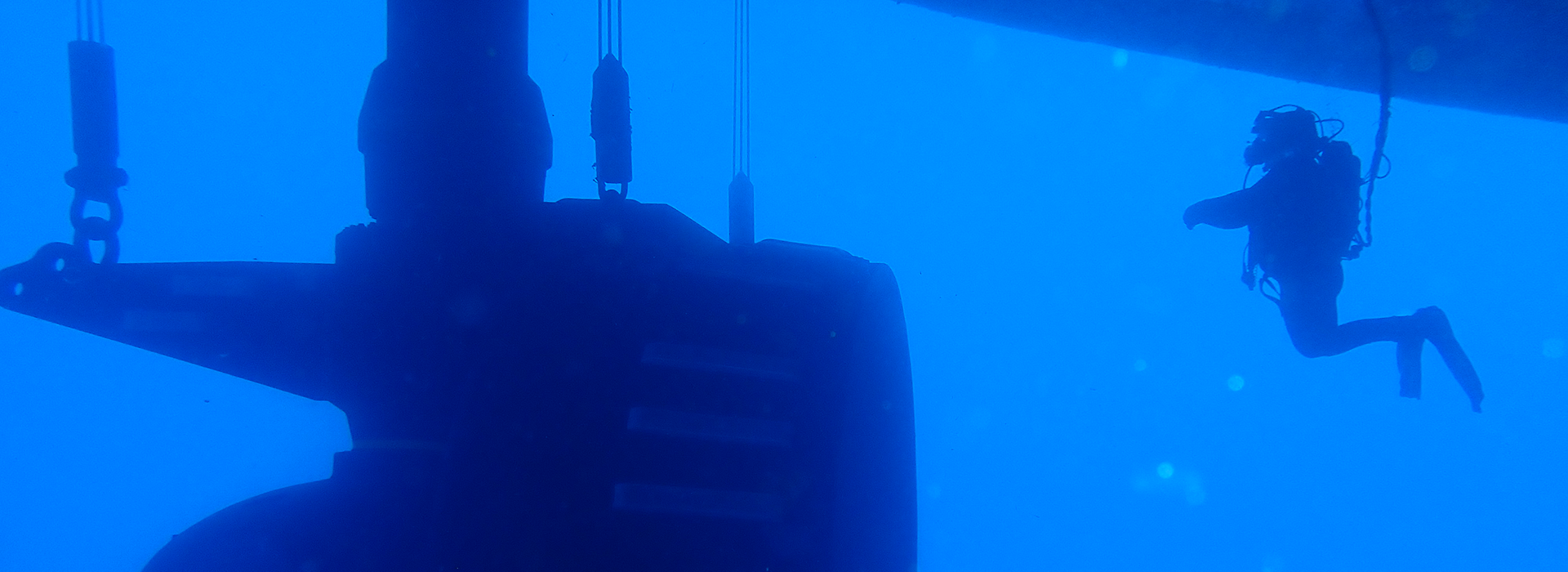

Wärtsilä Underwater Services (formerly Trident) started its journey in September 1993 as an underwater service provider with a team of two divers, specialising in repairing, overhauling, and servicing seagoing vessels, marine installations, and rigs for the commercial, energy, and navy markets.

Since then, it has established a far-reaching partner network of factory-trained, industry-certified diver technicians operating on a global scale, as well as a number of offices across Europe.

That, combined with its industry-specific product training programmes and access to Original Equipment Manufacturer (OEM) products and solutions, position it to offer technical maritime support and solutions when customers need it most while guaranteeing a high standard of service and commercial diving equipment.

Its innovative approach, outside-the-box thinking, and ability to handle warranty claims have proven invaluable to customers, which is why Wärtsilä Underwater Services is considered the OEM’s underwater service provider of choice.

Wärtsilä Underwater Services

Contact our 24/7 emergency support on

+31 115 61 2872 for assistance. You can also contact us via email at underwaterservices@wartsila.com.

Our underwater solutions eliminate the need for dry docking, saving time and money

Areas of Expertise

Our underwater maintenance and repair services are divided into the following areas of expertise.

- Machinery and equipment

- Propulsion

- Shaft sealing systems

- Shell plate repair

- Ship husbandry

- Oil and gas

Machinery and equipment

We have underwater factory-approved repair options available, executed by trained and certified technicians. Product improvement and procedure development together with major Original Equipment Manufacturers (OEMs) allow us to provide a safe, reliable, and cost-effective underwater service.

Our offerings include:

- tunnel thruster internal repairs, hub, blade/seal, and complete lower gearbox exchange;

- scrubber pipe repair

- stabiliser fin afloat repair and complete replacement;

- azimuthing thrusters repair and lower gear replacement;

- becker rudder approved underwater repairs;

- ICCP, speed log, and other sensor replacement and repair;

- engineering support and consultancy services; and

- rudder repairs and removal or re-installation.

Propulsion

Our in-house and external OEM training/certification programmes give underwater technicians a firm understanding of hydrodynamics, allowing them to evaluate and execute complex underwater propeller repairs. We advise owners and classification societies on the best propulsion and cost-effective repair solutions on-site, based on our initial underwater examination.

Our extensive experience acquired over the decades allows us to engineer and build innovative tools and equipment for underwater propeller repair solutions beyond existing methods. This means more economic, time-saving, and technically advanced propeller modifications and repair solutions for our customers.

Our propeller repair/modification services include:

- NDT or close visual inspection/evaluation and reporting in accordance with OEM and class standards;

- blade straightening (from 0 to 750mm into the blade and 45-50 mm in material thickness);

- static balancing in line with ISO 484 (class 1 or 2), following onsite calculations;

- damaged blade section and crack removal;

- leading and trailing edge repair and modifications;

- diameter and blade area reduction;

- remediation of propeller induced engine overload; and

- installation of energy-saving devices, like the Wärtsilä EnergoProFin.

Shaft sealing systems

We are your partner for commercial diving services on all floating structures.

We have a specialism in underwater ship maintenance, cleaning, and inspection, and our global fleet maintenance agreements are supported by all Wӓrtsilӓ Underwater Services locations and our approved vendors worldwide.

Work methods and procedures are shared globally with our partners to meet or exceed our client's expectations.

Our underwater maintenance services include:

- in-water class surveys;

- dry-docking extension surveys;

- pre-purchase inspection/surveys;

- damage assessment inspections;

- hull coating inspections;

- NDT/photo and video examinations;

- hull-coating efficiency treatment approved by paint manufacturers;

- high efficiency propeller polishing (< 0,2 micron); and

- temporary blankings to support any hull aperture exchange.

Shell plate repair

We’ve been delivering underwater wet/dry and hyperbaric welding solutions as a part of our portfolio since start-up in 1993.

Wet welding procedures were developed/approved for class A fillet welds. In combination with strategic alliance partners in 2014, an underwater wet welding V-Groove procedure was successfully implemented and accepted by DNV-GL. The diving training facility in the head office in Terneuzen, The Netherlands is constantly in use, training new staff on underwater welding applications.

Wet welding is a standard technology used on most of our projects on a daily basis. Permanent shell-plate repairs are executed using cofferdams designed/engineered in-house.

Our underwater Welding Services include:

- permanent shell plate repair;

- hull apertures installation (speed-log depth-sensor, overboard);

- wet weld repairs (temporary and permanent); and

- wet welding anodes replacement.

Ship husbandry

In 2005, we received the EMERGO Maritime Innovation Award in recognition of our OEM-approved underwater service for installing and servicing lip-type shaft seals. Since then, we’ve performed hundreds of seal repairs and overhauls on shafts with a diameter of up to 1100mm.

Its success is largely owing to our technical training, our experience in product design, and the emphasis we place on product testing, all of which have enabled us to deliver an exemplary service to the maritime industry, one which uses a widely recognized and accepted shaft seal overhaul method aligned with classification and manufacturer warranty standards.

In order to carry out the service safely and efficiently, we set up a lightweight, flexible, open habitat (FLEX-DAM) around the stern configuration, away from the natural elements and the dust generated in drydock. Its compact design is also more conducive to commercial air freight, allowing for swift mobilization in emergency situations.

Our underwater shaft seal repair services include:

- lip-type seal bonding and spacer ring installation or removal;

- wet repair and replacement of face-type seals (including Deep Sea Seals, Cedervall, Wӓrtsilӓ);

- CPP blade seal replacement;

- tunnel or azimuthing thruster shaft and blade seal upgrades; and

- stabiliser fin shaft seal and crux seal repairs.

Oil and gas

We’re getting more involved in projects on offshore floating structures as a result of our technical capability to support our oil and gas customers with the best cost-effective, time-saving solutions in all circumstances.

Over time, we’ve developed a strong reputation for being a globally present, reliable, fast-response partner when it comes to (emergency) underwater repairs.

Our underwater offshore services include:

- shell plate cleaning;

- SPS surveys;

- NDT inspections;

- azimuthing thruster exchange;

- underwater weld repairs; and

- cold lay-up support.

Downloads

Articles

Please fill in the form, we aim to respond within 1-2 business days depending on the enquiry. For an existing installation, provide all necessary details to identify the installation and the equipment. Fields indicated with an asterisk (*) are required.

Contact our 24/7 emergency support on

+31 115 61 2872 for assistance. You can also contact us via email at underwaterservices@wartsila.com.